CNC Engine Machine Services Engine Blueprinting

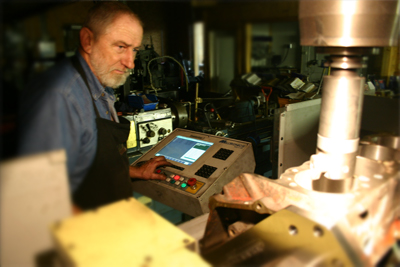

The engine block is set in the CNC machine with a balanced bar and engine specific bushing along the center axis of the engine block , this is to ensure block work is done on the engine’s crankshaft center-line. A second balanced bar is placed into the engine’s cam tunnel.and establishes the vertical center-line. An electronic probe, attached to the CNC machine, measures the engine’s bore size and spacing. The engine’s deck height in checked 6 places on each side of the engine block. The resulting readings appear on the CNC’s attached screen along with the engine’s particular factory blueprint specifications. Based on the amount of core shift and accuracy of the factory engine machining, you can choose to machine the engine block by either probed or factory Blueprint specifications.

The engine and head machining possibilities are seemingly endless. Bushing lifter bores, sleeving, splayed caps, buttress bolt cap conversions, boring, decking to specific heights, chamfering, stroker clearance at the bore and cam tunnel, dowel pin location, counter bored sleeve installation, MID Sleeve installation are just a very few of the more popular applications able to be performed with our Sunnen RMC CNC Machine.

Dennis Hawkins, owner of Precision Machine Service, said ” I was very fortunate to have RMC Engine Rebuilding Equipment, Inc.as my machine and application program supplier. Their wonderful supply of engine programs and a universal program for less common engines along with their endless patience in transitioning an “old school engine head” into the CNC age is greatly appreciated.