Engine Machine Shop Gallery

Muscle Car engines to rare vintage motors have passed through our engine machine shop doors for over 40+ years. Precision Machine Service wishes to share some of these high performance engines with you.

Maybe you would love for us to work on your specialized engine rebuild and add your engine’s photo to our Engine Gallery. If so, please let our expert machine shop team know and while rebuilding your engine, they will be sure to get a photo added. If you would like to discuss your engine rebuild project contact us for assistance.

Precision Machine Service exterior of the office, engine machine shop, welding garage and Dyno Testing Room.

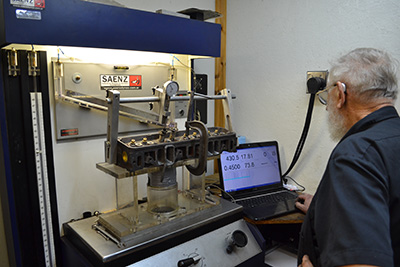

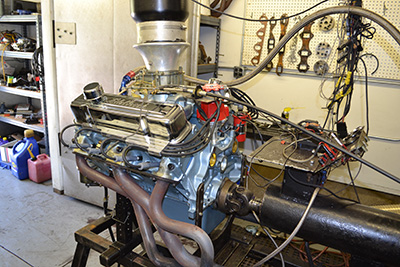

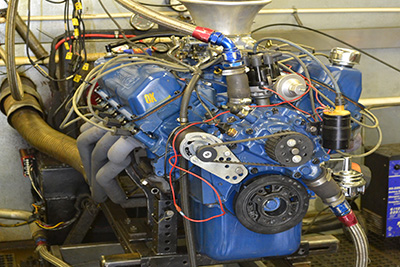

Dyno Testing engines for maximum performance. Dyno testing may involve several trial runs before and engine’s optimum horsepower rating is reached.

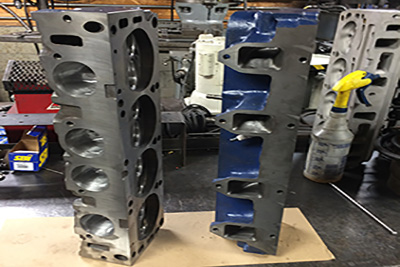

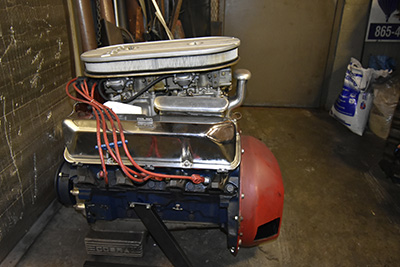

Australian River Racing, those boys take it serious. Check out this custom machined 632 Big Block engine done by Precision Machine Service.

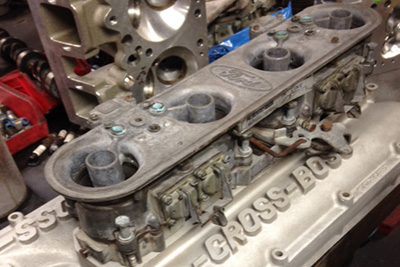

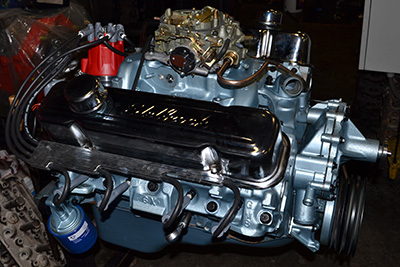

Our engine machine shop disassembled and went through this 427 Side Oiler for one of our customers. Engine has many Holman Moody parts..